Plastic

Non-contact temperature measurement of plastics is easy with Calex infrared pyrometers. In most cases, a general-purpose sensor with an adjustable emissivity setting will give excellent results.

Our range of PID controllers is compatible with traditional temperature probes as well as infrared temperature sensors, and is well-suited to the plastics industry, for applications including extrusion and injection moulding.

Thermoforming

Calex PyroMini infrared temperature sensors are ideal for thermoforming applications. The plastic sheet temperature is measured as it is heated to ensure the correct forming temperature is achieved, as well as during cooling after forming. Because the production rate is often limited by the cooling process, the faster the part can be removed from the mould, the faster the production rate. The sensor gives an accurate, instant temperature reading without the lag time associated with contact probes.

Detailed application notes: Thermoforming temperature measurement (PDF)

Blow Moulding

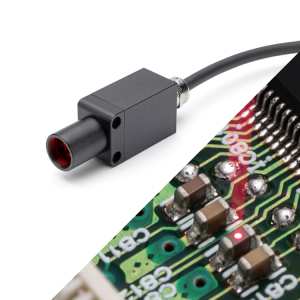

The temperature of the plastic bottle preform is measured before it is inflated. The small measured spot size and fast response time of Calex PyroCube infrared temperature sensors is ideal, making it easy to achieve consistent quality in the finished product.

Detailed application notes: Infrared temperature sensors for blow moulding (PDF)

Thin Plastic Film

Thin-film plastics are a special case and require sensors that measure certain wavelengths depending on the type of plastic. The PyroCube P is specialised for measuring some types of thin plastic film with minimal transmission. For measuring the temperature of thin plastic films, contact Calex for advice.

Other Applications in the Plastics Industry

Application notes: General plastic temperature measurement (PDF)

Suggested products

-

Pixsys ATR124

3-digit panel mounted indicating controller with NFC and dual setpointAlarm Output NFC configuration PID Control Temperature Display Very Low CostRead more -

ST633

Low-cost handheld pocket IR thermometerHandheld Low Temperature (-20 to 500°C) Measures Non-Reflective Surfaces Very Low Temperature (< -20°C)Read more -

Excelog 6

6-channel handheld temperature data logger with touch screenContact Probes Data Logging Handheld Multi-Channel PRT Input Pt100 Input RTD Input Temperature Display Thermocouple Input Touch Screen Interface USBRead more -

PyroSigma

Miniature pyrometer with built-in displayAlarm Output High Temperature (500 to 1000°C) Low Temperature (-20 to 500°C) Measures Non-Reflective Surfaces Miniature Temperature Display Very Low Cost Voltage OutputRead more -

PyroMini OEM

Low-cost pyrometer for machine manufacturers4-20 mA Output High Ambient Temperature 120C Low Temperature (-20 to 500°C) Measures Non-Reflective Surfaces Miniature Thermocouple Output Very Low Cost Voltage OutputRead more -

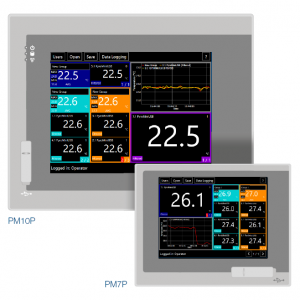

Industrial Panel PCs (Discontinued – contact Calex for alternatives)

PM7P and PM10PData Logging Multi-Channel Networkable RS485 Modbus Touch Screen Interface USBRead more -

PyroCube XS

For extremely small targets0-20 mA Output 4-20 mA Output Air or Water Cooling Available Data Logging Low Temperature (-20 to 500°C) mV Output Relay Output RS232 Modbus Small Measured Spot < 5 mm Temperature Display Touch Screen Interface Very Small Measured Spot < 1 mm Voltage OutputRead more -

PyroCube P

Thin film plastic temperature measurement0-20 mA Output 4-20 mA Output Air or Water Cooling Available Data Logging Low Temperature (-20 to 500°C) Measures Plastic Film mV Output Relay Output RS232 Modbus Temperature Display Touch Screen Interface Voltage OutputRead more -

PyroMiniUSB

For PC-based data acquisitionData Logging High Temperature (500 to 1000°C) Low Temperature (-20 to 500°C) Measures Non-Reflective Surfaces Miniature Temperature Display USBRead more -

PyroNFC

Smartphone-configurable pyrometer with voltage or thermocouple output - now with iOS app!Alarm Output High Temperature (500 to 1000°C) Low Temperature (-20 to 500°C) Measures Non-Reflective Surfaces Miniature NFC Thermocouple Output Very Low Cost Voltage OutputRead more -

PyroMiniBus

Miniature pyrometer with RS-485 Modbus for multi-channel systemsData Logging High Ambient Temperature 120C Low Temperature (-20 to 500°C) Measures Non-Reflective Surfaces Networkable Relay Output RS485 Modbus Temperature Display Touch Screen Interface Very Low CostRead more -

PyroTune

Emissivity adjuster for PyroEpsilon4-20 mA OutputRead more -

ST680 Series (discontinued)

High-performance IR thermometerData Logging Handheld High Temperature (500 to 1000°C) Low Temperature (-20 to 500°C) Measures Non-Reflective Surfaces Thermocouple Input USB Very Low Temperature (< -20°C)Read more -

ST642 (Discontinued – see ST633)

Low-cost handheld IR thermometer with adjustable emissivity and Type K Thermocouple inputHandheld Low Temperature (-20 to 500°C) Measures Non-Reflective Surfaces Thermocouple Input Very Low Temperature (< -20°C)Read more -

PM180

6-channel hub with data logging & alarms0-20 mA Output 4-20 mA Output Data Logging Networkable Relay Output RS485 Modbus Temperature Display Touch Screen Interface Voltage OutputRead more -

PyroEpsilon

Continuously variable emissivity4-20 mA Output Air or Water Cooling Available Low Temperature (-20 to 500°C) Measures Non-Reflective Surfaces Very Low CostRead more -

PyroCube S and F

High speed pyrometer for small targets and fast measurements0-20 mA Output 4-20 mA Output Air or Water Cooling Available Data Logging High Speed Low Temperature (-20 to 500°C) Measures Non-Reflective Surfaces Miniature mV Output Relay Output RS232 Modbus Small Measured Spot < 5 mm Temperature Display Touch Screen Interface Very Fast Response 1 ms Voltage OutputRead more -

PyroCouple

Simple, robust pyrometer with analogue output4-20 mA Output Air or Water Cooling Available Low Temperature (-20 to 500°C) Measures Non-Reflective Surfaces mV Output Thermocouple Output Very Low CostRead more