Non-Contact Infrared Sensors in the Food Processing Industry

Calex non-contact infrared temperature sensors are ideally suited for use in food processing and manufacturing industries, as they can be used without contaminating or disturbing the product.

The sensors have a very fast response time and can accurately measure the surface temperature of food substances moving on a conveyor belt, in vats with stirrers and even through glass jars. Typical applications include the manufacture of chocolate and toffee, baked products such as bread and biscuits, and frozen foods.

Measuring the surface temperature of food products

Foods are non-reflective and have a high emissivity at low temperatures, which makes them easy to measure using low-cost general-purpose long-wavelength (8–14 µm) sensors such as the PyroCouple.

The PyroUSB model PUA8 can measure temperatures as low as -40°C, making it ideal for measuring frozen food.

Measuring from food products on a conveyor or in a vat with a stirrer

Some of our sensors have peak and valley hold processing which can continuously output the temperature of objects on a conveyor, and ignore the gaps between them, or the surface temperature of liquids in a vat with a stirrer.

Measuring the surface temperature of food production equipment

For applications where the emissivity of the target could be lower than 0.95, such as when measuring the temperature of baking trays, we suggest using a sensor with an adjustable emissivity setting, like the PyroEpsilon, PyroNFC or PyroUSB.

Stainless steel surfaces, which are highly reflective and have a low emissivity, are usually best measured using a short wavelength (2 µm) sensor such as the PyroUSB model PUA2.

Measuring the temperature of food in glass containers

The PyroUSB model PUA2-151-LT can also be used to measure the temperature of hot food products inside glass containers (such as in sterilisation applications), as glass is usually transparent to infrared radiation at 2.2 µm.

Measuring at high or low ambient temperatures

Most Calex sensors operate at ambient temperatures from 0°C to 70°C, however, for use near ovens and heaters, some sensors have an optional air/water cooling jacket.

The PyroMini sensor is able to withstand ambient temperatures up to 120°C or 180°C without cooling.

If the ambient temperature is below freezing, the air/water jacket can be used to keep the sensor heated above 0°C and prevent ice from forming on the lens.

Measuring in tight spaces

The PyroNFC is a small sensor with a side-entry cable which makes it ideal for mounting in tight spaces. This sensor is fully-configurable via a smartphone app. With a voltage or Type K thermocouple output option, it can quickly and easily be used to replace existing contact probes.

Measuring in multiple locations

For measuring the temperature in multiple locations on a food production line, the PyroMiniBus digital sensor with RS485 Modbus communications is ideal.

Sensors can be connected to a monitoring system such as a panel PC or SCADA. We can supply industrial panel PCs, pre-loaded with Windows, which allow temperature data to be accessed in real-time.

Optionally, up to 6 PyroMiniBus sensors can be connected, via the PMBHUB junction box, to a local display (model PM180) with data logging, alarms and RS485 Modbus master/slave interfaces.

A network of PyroMiniBus sensors can significantly reduce the cost and complexity of cabling, compared to using sensors with an analogue output.

Specialist applications

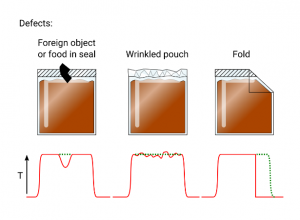

Our PyroCube sensors can measure the surface temperature from small targets or thin plastic films. There is a model with a fast 1 ms response time which can be used in applications such as food pouch sealing. The sensor helps detect foreign objects or folds in the pouch seal by providing a detailed temperature profile of the seal area.

Hazardous applications

In applications involving powdered food materials, such as flour milling, there can be an explosion risk; for such hazardous applications we have the ExTemp intrinsically safe sensor.

Food for thought!

All the above sensors have a tough lens made of either germanium or silicon (not glass). However, if additional safeguards are required, a plastic window is available to improve protection of the lens against mechanical damage, and to help contain fragments of the lens in case any damage does occur.

Dust and steam on the sensor lens can significantly affect the accuracy of measurement. If this is an issue, an air purge collar is recommended to help keep the sensor lens clean and dry, and the amount of steam should be minimised by extraction.

We can also supply low-cost handheld infrared temperature sensors which are particularly useful as a low-cost way to test if a planned installation of fixed-mount sensors could be successful.

Get in touch

If you have any questions about the use of infrared temperature sensors in food processing, please do not hesitate to contact Calex and we will do our best to help you.