Tag Archives: PyroCube

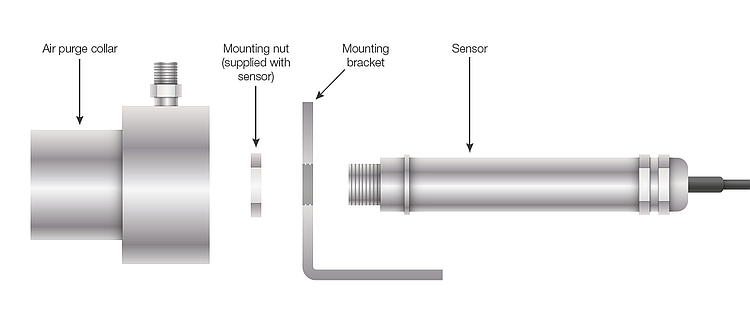

The lens of every infrared temperature sensor must be kept clean and dry to ensure the pyrometer has a clear view of the target. The simplest way to do this is to purge the lens continuously with clean air, preventing dust and moisture from reaching it. Here is how to use the air purge collar.

Measuring the temperature of plastic preforms in blow moulding applications is easy with Calex infrared temperature sensors. An accurate measurement can be obtained as fast as 1 millisecond, even from the smallest preform, without touching the preform.

Calex has achieved success in measuring the surface temperature of extruded aluminium profiles using low-cost non-contact pyrometers. Measurements were taken by a leading manufacturer of extruded profiles at the press exit and after the quench, and good results were obtained with short-wavelength single-wavelength pyrometers, even with significant steam near the quench box.

Most infrared temperature sensors have an adjustable emissivity setting. Here’s how to use this powerful feature to achieve accurate measurements from a variety of surfaces.

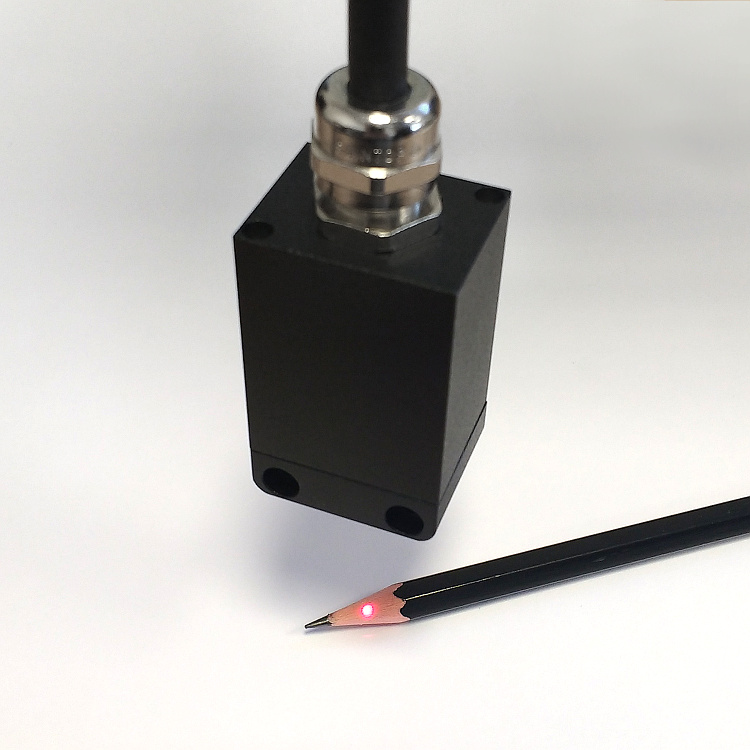

Technical advice from Calex Electronics on choosing a suitable infrared temperature sensor to measure small targets.

If you need a pyrometer with a very small measurement spot size, a very fast response time, or continuous built-in aiming, the PyroCube is ideal. Here are some applications where each of these features can be used.