Tag Archives: Choosing a Sensor

Powerful processing features are available on many Calex infrared temperature sensors as standard. Learn more about these features, and some of the sensors that provide them.

Calex non-contact infrared temperature sensors are ideally suited for use in food processing and manufacturing industries, as they can be used without contaminating or disturbing the product. The sensors have a very fast response time and can accurately measure the surface temperature of food substances moving on a conveyor belt, in vats with stirrers and … Continue reading Non-Contact Infrared Sensors in the Food Processing Industry

Calex short wavelength (2.0 to 2.6 µm) infrared temperature sensors are suitable for accurately measuring the surface temperature of non-metals and some metals at high or low temperatures. These sensors have adjustable emissivity settings, reflected energy compensation and peak and valley hold processing, making them particularly suitable for measuring hot objects in a furnace or on … Continue reading Comparison of Short Wavelength Infrared Temperature Sensors

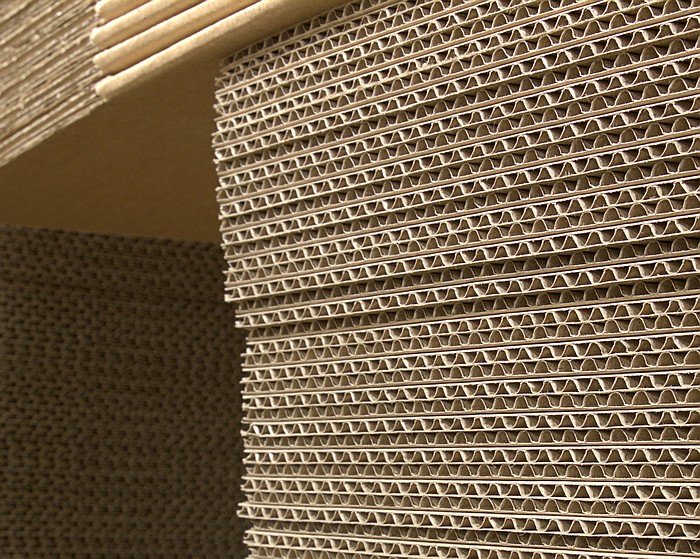

Calex non-contact infrared temperature sensors are now being used with excellent results by leading manufacturers of corrugated cardboard worldwide. Here’s how.

Calex normally recommends using a short-wavelength infrared temperature sensor to measure the temperature of metals, instead of a general-purpose type, because it is more accurate. But why is it more accurate? Here are the reasons.

A handheld infrared thermometer is a useful diagnostic tool. Here are some tips on how to achieve accurate measurements, and how the handheld thermometer can be used to find out if a planned installation of fixed-mount sensors could be successful.

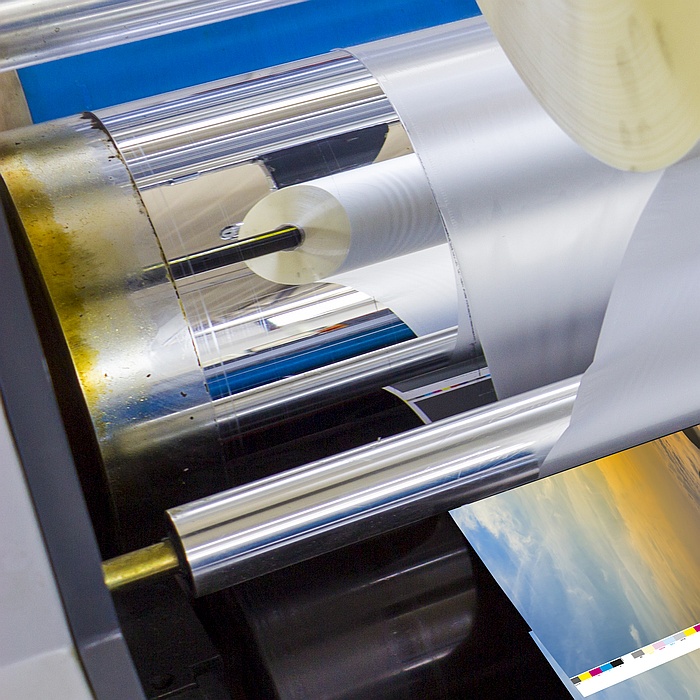

Measuring the temperature of plastic preforms in blow moulding applications is easy with Calex infrared temperature sensors. An accurate measurement can be obtained as fast as 1 millisecond, even from the smallest preform, without touching the preform.

Calex has achieved success in measuring the surface temperature of extruded aluminium profiles using low-cost non-contact pyrometers. Measurements were taken by a leading manufacturer of extruded profiles at the press exit and after the quench, and good results were obtained with short-wavelength single-wavelength pyrometers, even with significant steam near the quench box.

Most infrared temperature sensors have an adjustable emissivity setting. Here’s how to use this powerful feature to achieve accurate measurements from a variety of surfaces.

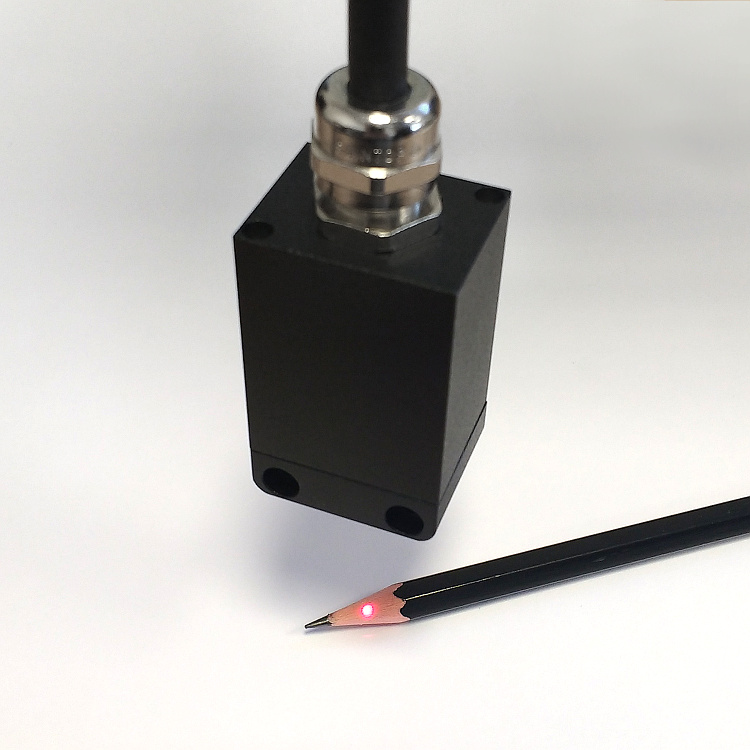

Technical advice from Calex Electronics on choosing a suitable infrared temperature sensor to measure small targets.