Tag Archives: PyroMini

The new Gooseneck Mount is the easiest, quickest way to adjust the aim of a Calex infrared temperature sensor.

Calex short wavelength (2.0 to 2.6 µm) infrared temperature sensors are suitable for accurately measuring the surface temperature of non-metals and some metals at high or low temperatures. These sensors have adjustable emissivity settings, reflected energy compensation and peak and valley hold processing, making them particularly suitable for measuring hot objects in a furnace or on … Continue reading Comparison of Short Wavelength Infrared Temperature Sensors

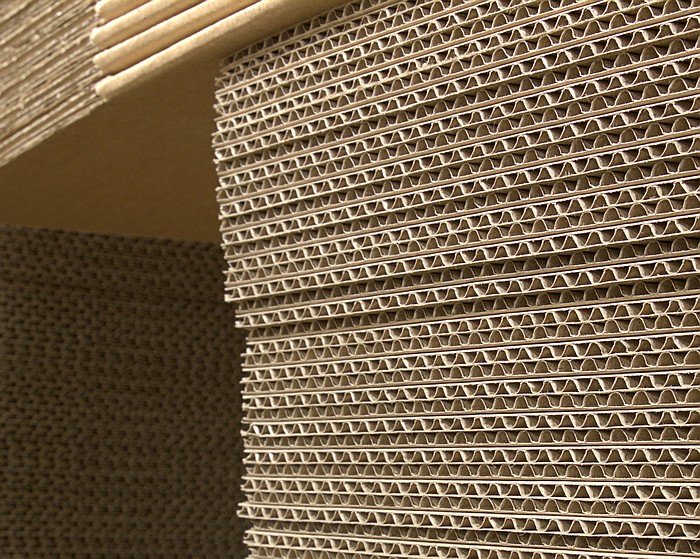

Calex non-contact infrared temperature sensors are now being used with excellent results by leading manufacturers of corrugated cardboard worldwide. Here’s how.

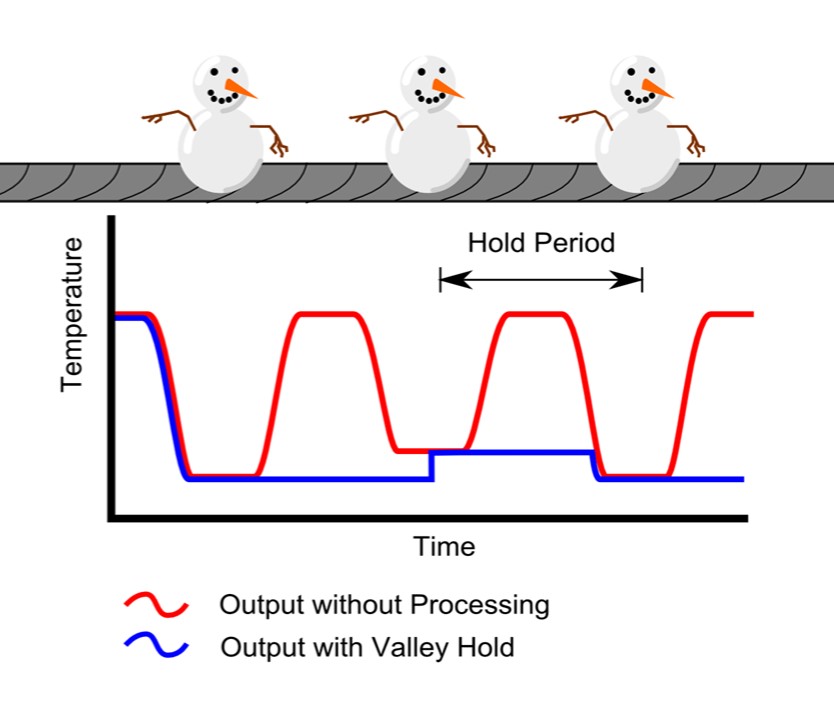

Many of our infrared temperature sensors have a feature called Peak or Valley Hold Processing. What does this feature do, and when should you use it?

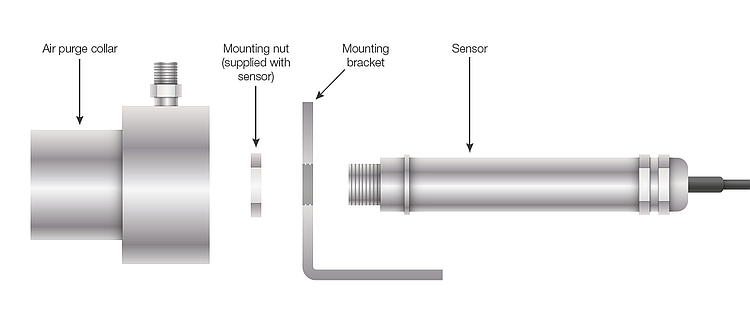

The lens of every infrared temperature sensor must be kept clean and dry to ensure the pyrometer has a clear view of the target. The simplest way to do this is to purge the lens continuously with clean air, preventing dust and moisture from reaching it. Here is how to use the air purge collar.

The new multi-channel temperature measurement software, CalexSoft 2, is now available as a beta release.

Most infrared temperature sensors have an adjustable emissivity setting. Here’s how to use this powerful feature to achieve accurate measurements from a variety of surfaces.

Non-contact temperature measurement is now possible in areas of high ambient temperature with no need for sensor cooling using air or water. This brings several benefits, including cost reduction, better safety, and improved product quality in manufacturing processes.