Food

The temperature of food products is easy to measure using infrared thermometry, as they are usually non-reflective.

Calex sensors, monitoring the temperature of food items on a conveyor, can be configured for peak or valley hold processing, so the temperature of the most recent target is held while the next target is moved in front of the sensor. Successful applications also include chocolate and toffee manufacture.

![]() Detailed application notes: chocolate and toffee manufacture (PDF)

Detailed application notes: chocolate and toffee manufacture (PDF)

Flour milling

Temperature monitoring is essential in environments where overheating can cause an explosion risk, for example, a large system of PyroBus sensors with air purge collars may be used to monitor multiple rollers in flour mills so that dangerously high temperatures can be noticed before the combustible flour dust can catch fire.

![]() Flour mill rollstand temperature monitoring with the PyroBus IR sensor (PDF)

Flour mill rollstand temperature monitoring with the PyroBus IR sensor (PDF)

Lens Material

Calex sensors have a tough germanium or silicon (not glass) lens, and are being used in food applications around the world. However, if additional safeguards are required, a plastic window is available to protect the lens of the sensor from damage, and to contain fragments of lens in case of damage.

This application note describes how a special Calex sensor is being used, in the food industry, with a plastic window such as this.

![]() Right-angled infrared temperature sensor with protective plastic window (PDF)

Right-angled infrared temperature sensor with protective plastic window (PDF)

Other applications

![]() Detailed application notes: infrared temperature measurement in food safety (PDF)

Detailed application notes: infrared temperature measurement in food safety (PDF)

![]() Food temperature measurement through glass jars using the PyroUSB 2.2 (PDF)

Food temperature measurement through glass jars using the PyroUSB 2.2 (PDF)

Suggested products

-

ST633

Low-cost handheld pocket IR thermometerHandheld Low Temperature (-20 to 500°C) Measures Non-Reflective Surfaces Very Low Temperature (< -20°C)Read more -

Excelog 6

6 Channel Handheld Temperature Data Logger with Touch ScreenContact Probes Data Logging Handheld Multi-Channel PRT Input Pt100 Input RTD Input Temperature Display Thermocouple Input Touch Screen Interface USBRead more -

PyroSigma

Miniature pyrometer with built-in displayAlarm Output High Temperature (500 to 1000°C) Low Temperature (-20 to 500°C) Measures Non-Reflective Surfaces Miniature Temperature Display Very Low Cost Voltage OutputRead more -

PyroMini OEM

Low-cost pyrometer for machine manufacturers4-20 mA Output High Ambient Temperature 120C Low Temperature (-20 to 500°C) Measures Non-Reflective Surfaces Miniature Thermocouple Output Very Low Cost Voltage OutputRead more -

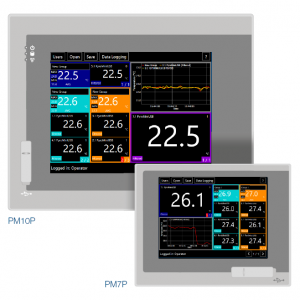

Industrial Panel PCs (Discontinued – contact Calex for alternatives)

PM7P and PM10PData Logging Multi-Channel Networkable RS485 Modbus Touch Screen Interface USBRead more -

PyroCube P

Thin film plastic temperature measurement0-20 mA Output 4-20 mA Output Air or Water Cooling Available Data Logging Low Temperature (-20 to 500°C) Measures Plastic Film mV Output Relay Output RS232 Modbus Temperature Display Touch Screen Interface Voltage OutputRead more -

PyroMiniUSB

For PC-based data acquisitionData Logging High Temperature (500 to 1000°C) Low Temperature (-20 to 500°C) Measures Non-Reflective Surfaces Miniature Temperature Display USBRead more -

PyroNFC

Smartphone-configurable pyrometer with voltage or thermocouple output - now with iOS app!Alarm Output High Temperature (500 to 1000°C) Low Temperature (-20 to 500°C) Measures Non-Reflective Surfaces Miniature NFC Thermocouple Output Very Low Cost Voltage OutputRead more -

PyroMiniBus

Miniature pyrometer with RS-485 Modbus for multi-channel systemsData Logging High Ambient Temperature 120C Low Temperature (-20 to 500°C) Measures Non-Reflective Surfaces Networkable Relay Output RS485 Modbus Temperature Display Touch Screen Interface Very Low CostRead more -

ST680 Series (discontinued)

High-performance IR thermometerData Logging Handheld High Temperature (500 to 1000°C) Low Temperature (-20 to 500°C) Measures Non-Reflective Surfaces Thermocouple Input USB Very Low Temperature (< -20°C)Read more -

ST642

Low-cost handheld IR thermometer with adjustable emissivity and Type K Thermocouple inputHandheld Low Temperature (-20 to 500°C) Measures Non-Reflective Surfaces Thermocouple Input Very Low Temperature (< -20°C)Read more -

PM180

6-channel hub with data logging & alarms0-20 mA Output 4-20 mA Output Data Logging Networkable Relay Output RS485 Modbus Temperature Display Touch Screen Interface Voltage OutputRead more -

PyroCube S and F

High speed pyrometer for small targets and fast measurements0-20 mA Output 4-20 mA Output Air or Water Cooling Available Data Logging High Speed Low Temperature (-20 to 500°C) Measures Non-Reflective Surfaces Miniature mV Output Relay Output RS232 Modbus Small Measured Spot < 5 mm Temperature Display Touch Screen Interface Very Fast Response 1 ms Voltage OutputRead more -

PyroCouple

Simple, robust pyrometer with analogue output4-20 mA Output Air or Water Cooling Available Low Temperature (-20 to 500°C) Measures Non-Reflective Surfaces mV Output Thermocouple Output Very Low CostRead more -

ExTemp

Intrinsically Safe for hazardous areas4-20 mA Output High Temperature (500 to 1000°C) Intrinsically Safe Low Temperature (-20 to 500°C) Measures Non-Reflective Surfaces USBRead more