What's Hot

Powerful processing features are available on many Calex infrared temperature sensors as standard. Learn more about these features, and some of the sensors that provide them.

Calex non-contact infrared temperature sensors are ideally suited for use in food processing and manufacturing industries, as they can be used without contaminating or disturbing the product. The sensors have a very fast response time and can accurately measure the surface temperature of food substances moving on a conveyor belt, in vats with stirrers and … Continue reading Non-Contact Infrared Sensors in the Food Processing Industry

Calex short wavelength (2.0 to 2.6 µm) infrared temperature sensors are suitable for accurately measuring the surface temperature of non-metals and some metals at high or low temperatures. These sensors have adjustable emissivity settings, reflected energy compensation and peak and valley hold processing, making them particularly suitable for measuring hot objects in a furnace or on … Continue reading Comparison of Short Wavelength Infrared Temperature Sensors

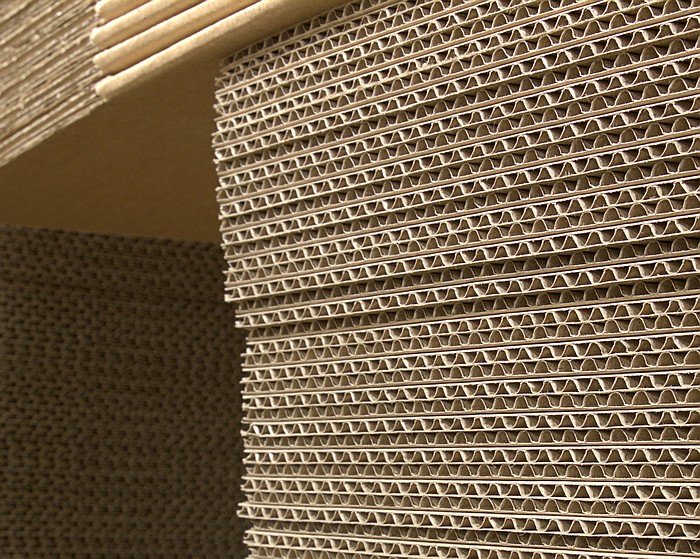

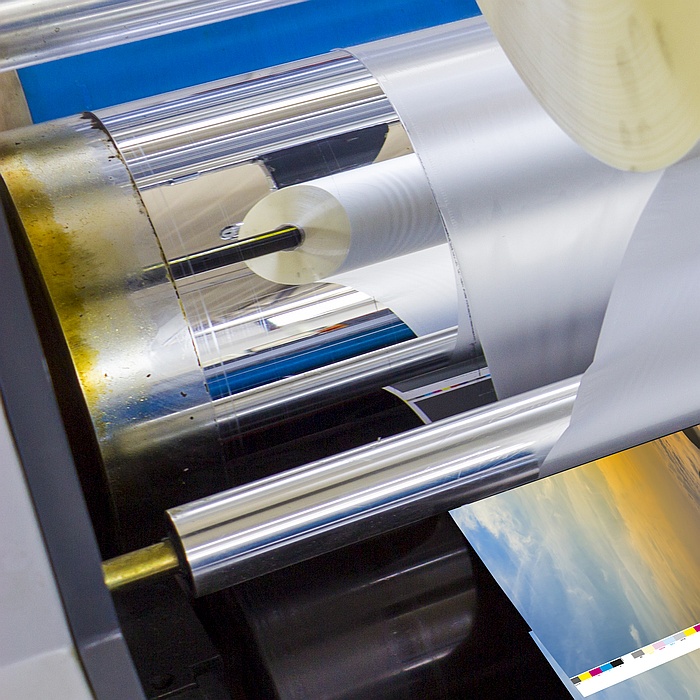

Calex non-contact infrared temperature sensors are now being used with excellent results by leading manufacturers of corrugated cardboard worldwide. Here’s how.

Blackbody calibration sources from Calex allow the calibration of infrared temperature sensors with low uncertainty. This article explains what makes the best blackbody calibration source for a given application and what you should consider when choosing one.

Infrared temperature sensors are commonly used in industry to control aspects of the process such as heaters, cooling systems and line speed. One of the simplest ways to measure temperature without contact and obtain a control output is to use a Calex PyroCouple pyrometer and a low-cost indicating controller such as the ATR121. Here’s how.

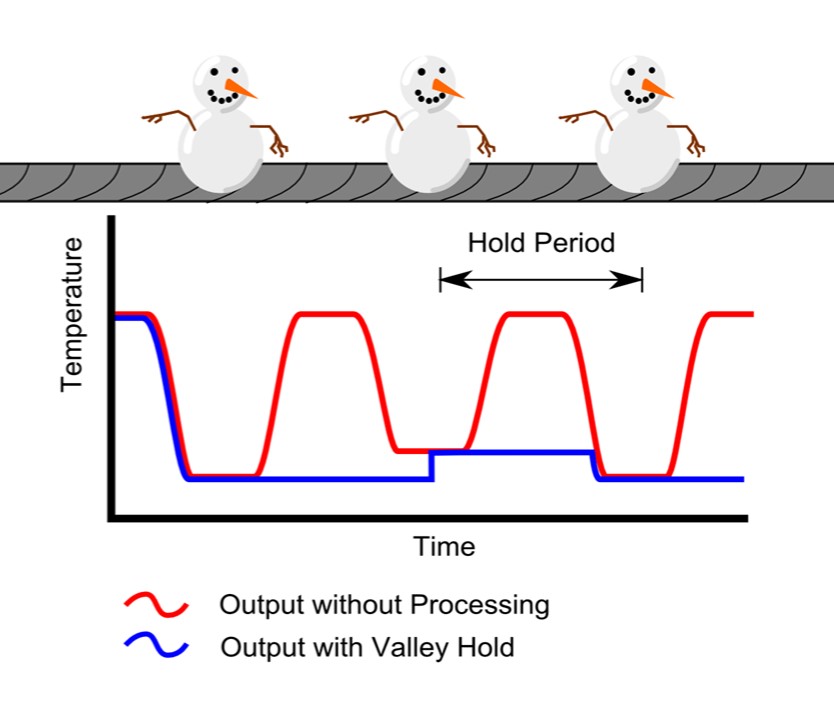

Many of our infrared temperature sensors have a feature called Peak or Valley Hold Processing. What does this feature do, and when should you use it?

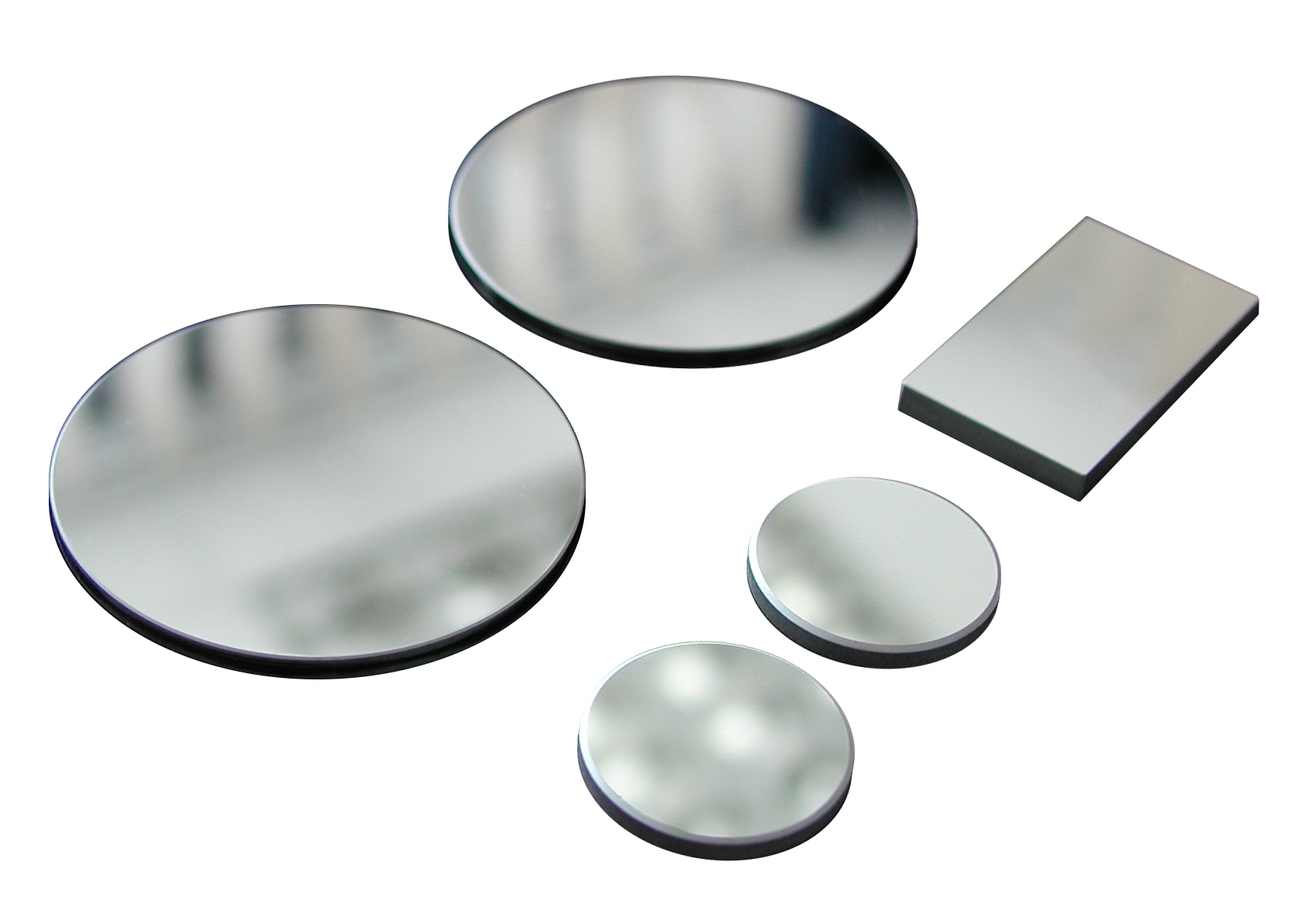

Calex can supply protective windows for pyrometers, and IR-transmissive viewport windows. This brief summary aims to help you to choose a suitable window. Protective Windows Protective windows, such as PWS and PWL, are ideal for use in the food and pharmaceutical industries. They protect the lens of Calex infrared temperature sensors by preventing contamination and/or … Continue reading Which Viewport Windows are Suitable for Calex Infrared Temperature Sensors?

Calex normally recommends using a short-wavelength infrared temperature sensor to measure the temperature of metals, instead of a general-purpose type, because it is more accurate. But why is it more accurate? Here are the reasons.

Modbus is a communication protocol for networks of devices, including Calex infrared temperature sensors such as the PyroMiniBus. Our own specialised hardware makes it easy to take measurements and configure sensors without any programming knowledge, however it is also possible to use third-party software to communicate with Modbus devices. A little understanding of Modbus is … Continue reading How to Use Third Party Modbus Software with Calex Sensors