General Specifications

Temperature Range

General purpose models: -20°C to 1000°C

Short-wavelength models: 100°C to 2000°C

Temperature range varies by model (see "Ordering")

Output

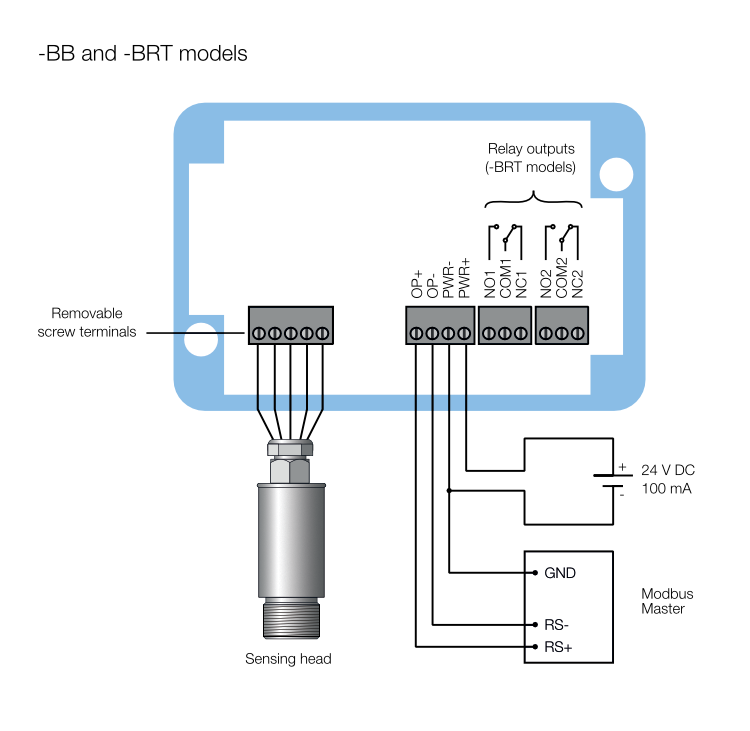

4-20 mA or RS485 Modbus (Up to 247 sensors may be installed on a single Modbus network)

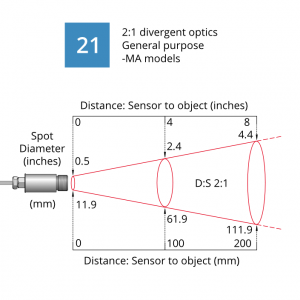

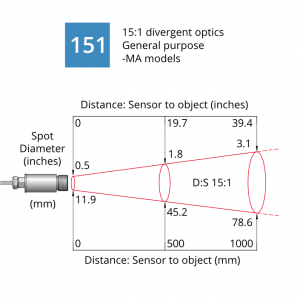

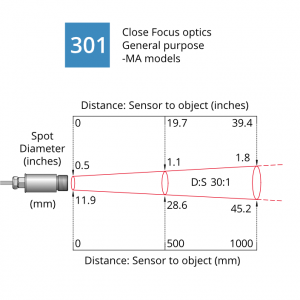

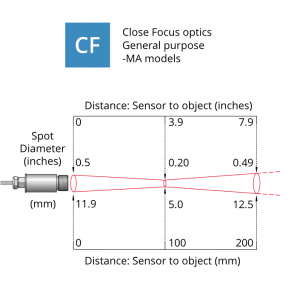

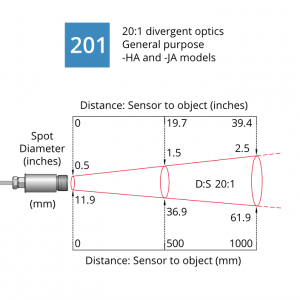

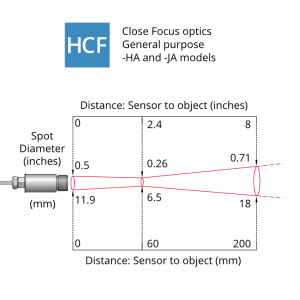

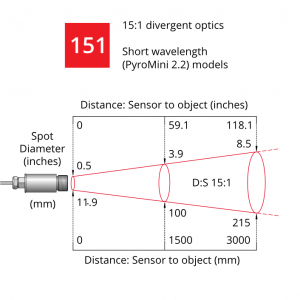

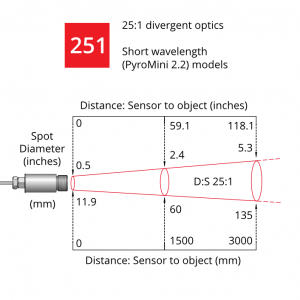

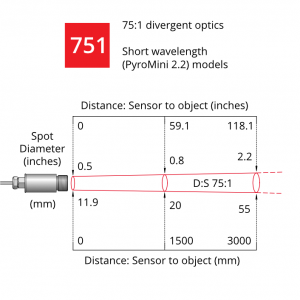

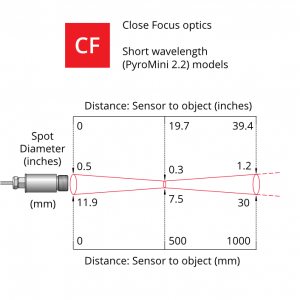

Field of View

Choice of wide-angle or focussed optics (see Field of View Diagrams below)

Accuracy

General purpose models: ± 1°C or 1% of reading, whichever is greater

Short-wavelength models: ± 2°C or 1% of reading, whichever is greater

Repeatability

± 0.5°C or 0.5% of reading, whichever is greater

Emissivity Setting

General purpose models: Adjustable, 0.20 to 1.00

Short-wavelength models: Adjustable, 0.10 to 1.00

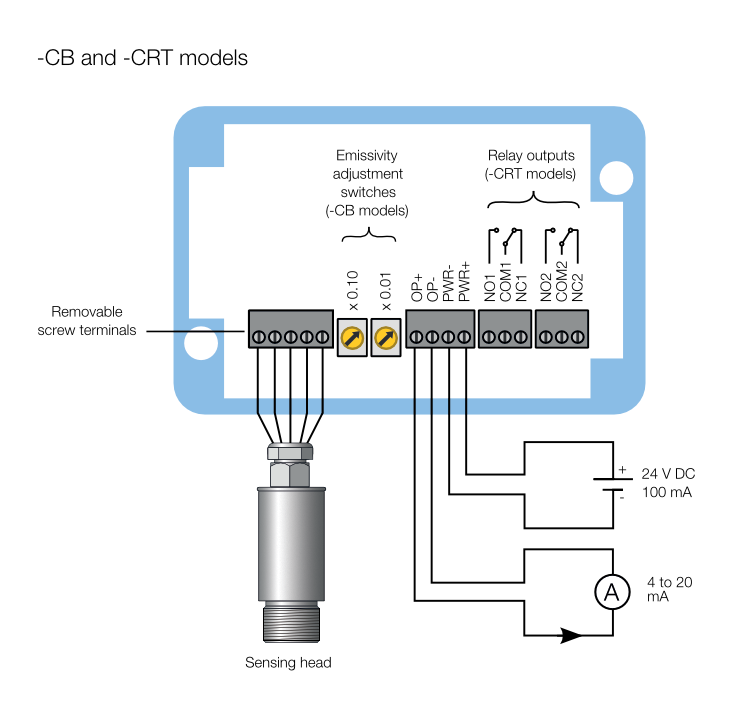

Emissivity Setting Method

-CB models: via two rotary switches in electronics module

-BB and -BRT models: via RS485 Modbus

-CRT and -BRT models: via touch screen

Response Time, t90

240 ms (90% response)

Spectral Range

General purpose models: 8 to 14 μm

Short-wavelength models: 2.0 to 2.6 µm

Supply Voltage

24 V DC ± 5%

Maximum Current Draw

100 mA

Max. Loop Impedance (-CB and -CRT models)

900 Ω (4-20 mA output)

Alarm Relays (-CRT and -BRT models)

2 x Single Pole Changeover alarm relays, rated 24 V DC, 1 A, isolated 500 V DC

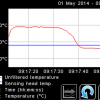

Data Logging Specifications

Data Logging Interval

1 to 86,400 seconds (1 day)

MicroSD Card

Max. capacity: 32 GB (not included, available separately)

Internal Clock Battery

1 x BR 1225 3V (not included)

Variables Logged

Target temperature, sensing head temperature, electronics module temperature, max, min, average, emissivity setting, reflected energy compensation temperature, alarm events

Configurable Parameters

Sample period, number of samples, scheduled start date and time

Touch Screen Interface Specifications

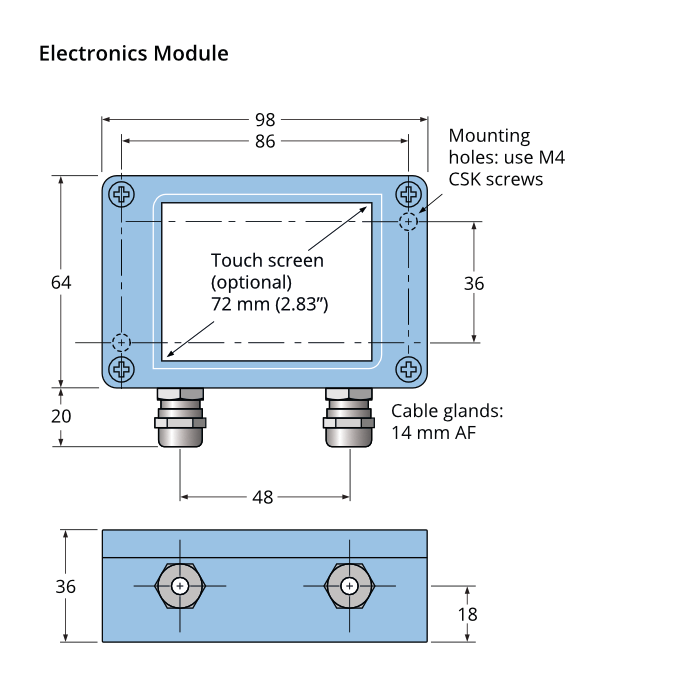

Touch Screen Display Format

2.83” (72 mm) resistive touch TFT, 320 x 240 pixels, backlit

Configurable Parameters

Temperature range, temperature units, emissivity setting, reflected energy compensation, alarms, signal processing, Modbus address (-BRT models), date and time, data logging

Temperature Units

°C or °F configurable

Temperature Resolution

0.1°

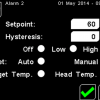

Alarm Configuration

Two alarms with adjustable level, individually configurable as HI or LO. Alarm 2 can be set to target temperature or sensing head internal temperature

Signal Processing

Average, peak hold, valley hold, minimum, maximum

Please note: The given measured spot size contains 90% of the energy detected by the sensor. We normally recommend the target is at least twice as large as the given measured spot for maximum accuracy.

Sensors may be used at longer distances than the above diagrams show. There is no maximum measurement distance in clean air, and accuracy does not change with distance; this is because the PyroMini detects only the wavelengths of infrared radiation that are not absorbed by the atmosphere.

Mechanical Specifications

Construction (Sensing Head)

Stainless Steel 316

Construction (Electronics Module)

Die Cast Aluminium

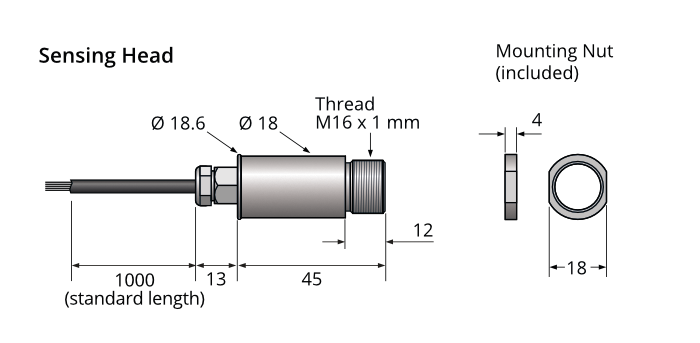

Major Dimensions (Sensing Head)

18(dia.) x 45(l) mm (see diagram on data sheet)

Major Dimensions (Electronics Module)

98(w) x 64(h) x 36(d) mm

Mounting (Sensing Head)

M16 x 1 mm thread

Mounting (Electronics Module)

Requires two M4 screws for wall mounting (see diagram on data sheet)

Cable Length (sensing head to electronics module)

1 m (standard), up to 30 m (optional)

Weight with 1 m cable

390 g (approx)

Cable Connections

Removable screw terminal blocks (see "Connections" on data sheet)

Conductor size: 28 AWG to 18 AWG

Output Cable Gland

Suitable for cable diameters 3.0 to 6.5 mm

Electromagnetic Compatibility Standards

Conforms with EN61326-1, EN61326-2-3 (Electrical Equipment for Measurement, Control and Laboratory Use – EMC Requirements – Industrial)

Environmental Specifications

Environmental Rating

Ambient Temperature Range

Relative Humidity

CE Marked

RoHS Compliant

Sensing Head

Environmental RatingIP65 (NEMA 4)

Ambient Temperature RangeGeneral Purpose models: Ranges from 0°C to 180°C, depending on model (see "Ordering"). Short Wavelength models: 0°C to 70°C

Relative HumidityMaximum 95% non-condensing

CE MarkedYes

RoHS CompliantYes

Electronics Module (without touch screen)

Environmental RatingIP65 (NEMA 4)

Ambient Temperature Range0°C to 60°C

Relative HumidityMaximum 95% non-condensing

CE MarkedYes

RoHS CompliantYes

Electronics Module (with touch screen)

Environmental Rating-

Ambient Temperature Range0°C to 60°C

Relative HumidityMaximum 95% non-condensing

CE MarkedYes

RoHS CompliantYes

The unique features of the PyroMini make it ideal for applications in a wide range of industries. For example, some typical uses include:

Typical Applications

Food

Peak or valley hold processing makes the PyroMini ideal for measuring food temperature in vats, where stirring machinery interrupts the sensor's view of the food surface, and for measuring the temperature of food products on conveyors to ignore readings of the conveyor temperature. Data logging to MicroSD Card means the PyroMini may be used to satisfy HACCP requirements.

Hot stainless steel surfaces above 100°C can be measured quickly and accurately with the PyroMini 2.2. Applications include burner control in conveyor ovens and dryers.

Paper

Models with high-temperature sensing head (up to 180°C ambient) may be used in hot environments in corrugated board manufacturing and paper drying.

Dryer cylinder surface temperatures exceeding 100°C (such as in linerboard manufacturing) may be measured directly with the PyroMini 2.2. See also the PyroUSB 2.2 for temperatures below 100°C (in the manufacture of finer paper types).

Plastics

In thermoforming, the 180°C sensing head is ideal for measuring the plastic sheet preheat temperature where the ambient temperature is high, without the need for cooling

Paint and Adhesive Curing

The high-temperature sensing head may be placed inside curing ovens up to 180°C without cooling. It is also ideal for use with infrared curing heaters.

Steel industry

Short-wavelength 2.2 μm sensors are better-suited to measuring steel surface temperature than general-purpose 8 to 14 μm models. Contact Calex for advice on measurement locations on annealing lines, furnaces, rolling mills and railway rail manufacturing.

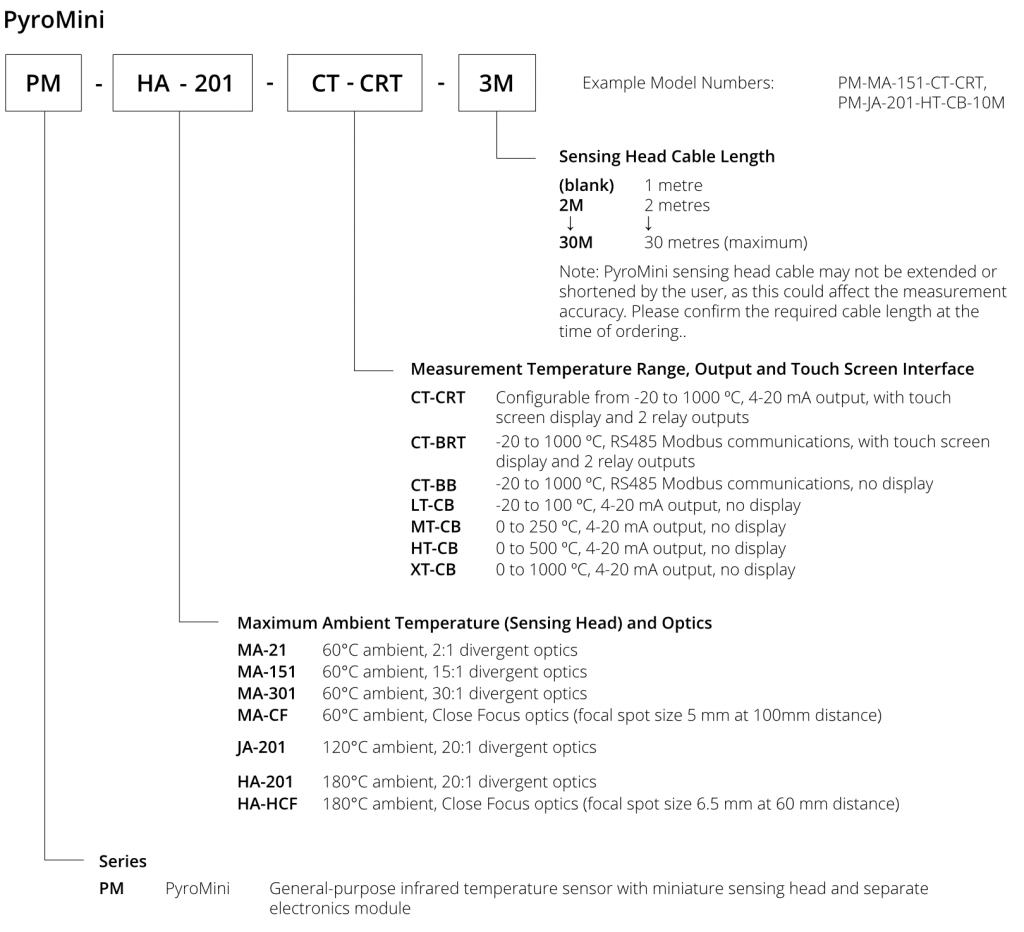

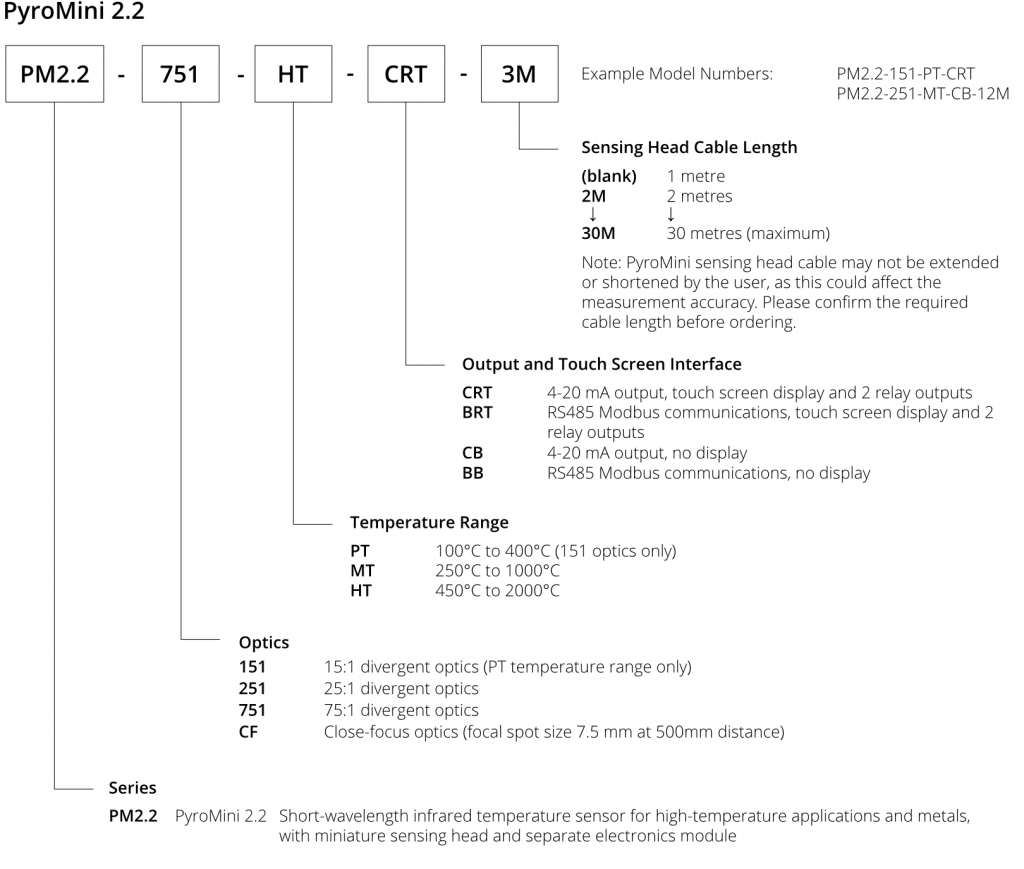

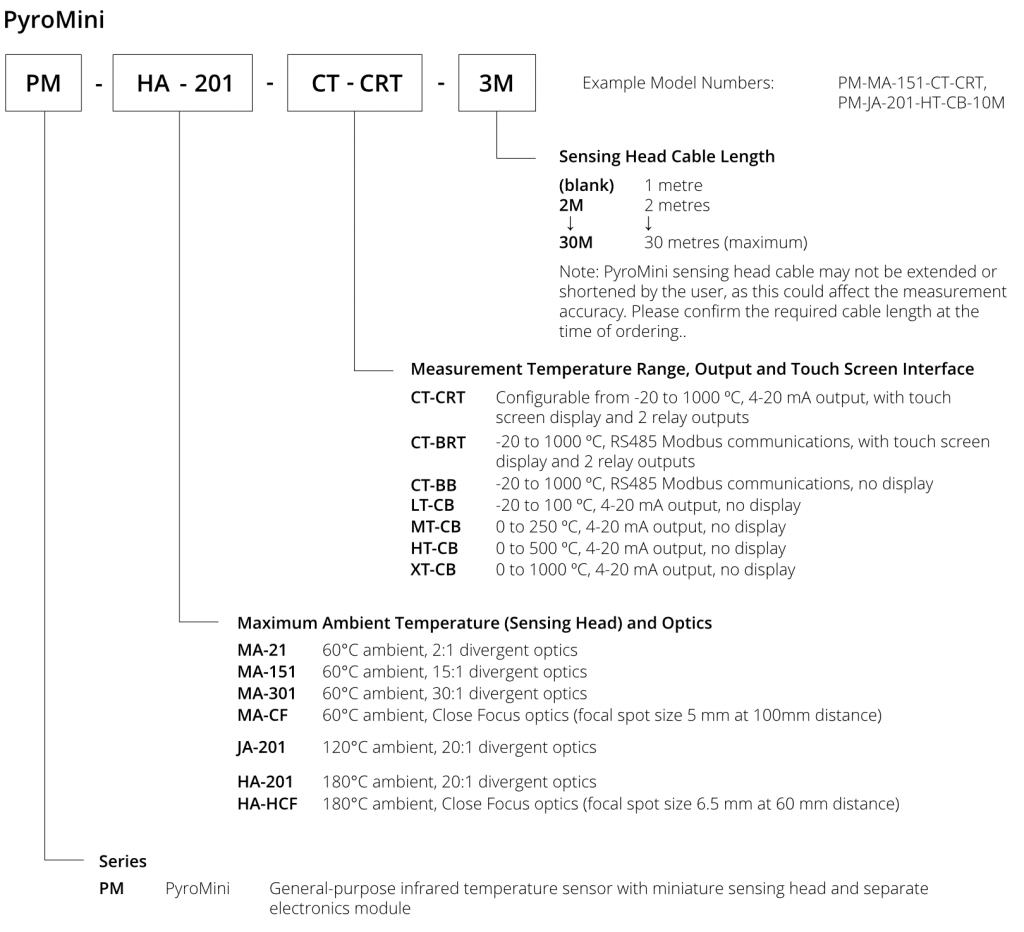

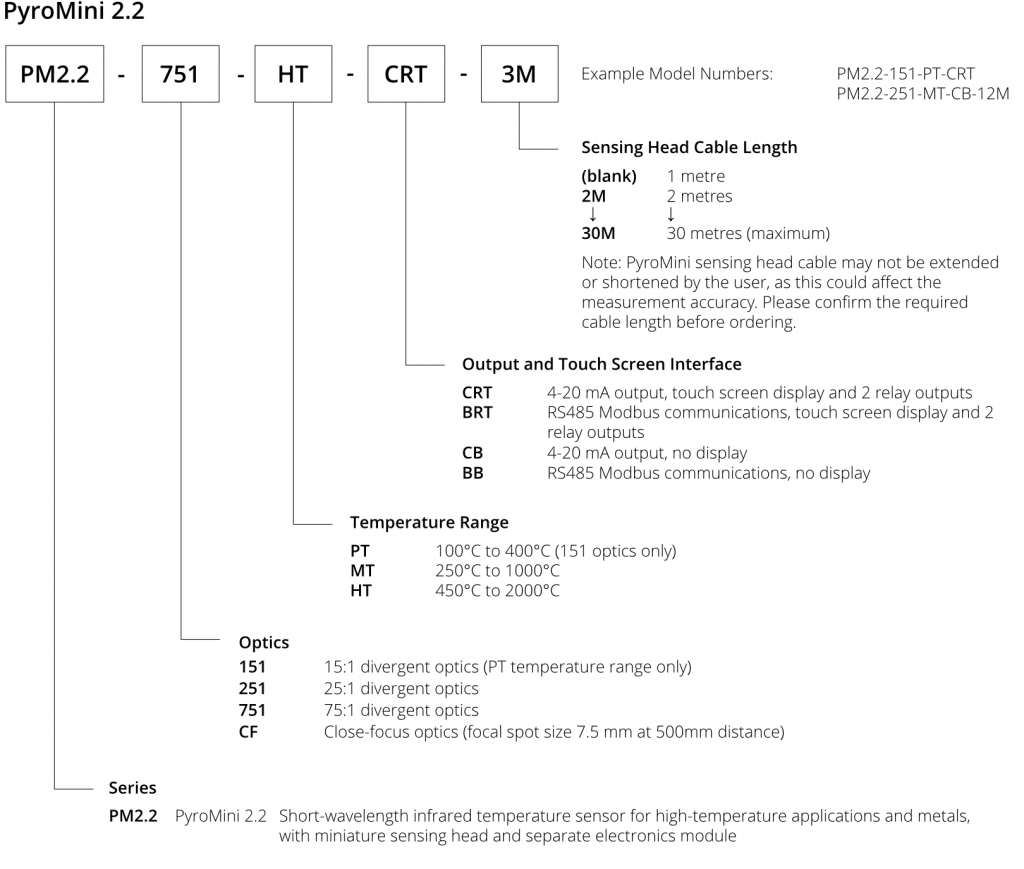

The PyroMini is a two-piece sensor with a miniature sensing head and separate electronics module. Each model number includes both parts.

Model Numbers

(click images to enlarge)

General purpose (8-14 µm) PyroMini models

for non-reflective non-metals

Short wavelength (2.0 to 2.6 µm) PyroMini 2.2 models

for improved performance on high-temperature targets and reflective iron or steel surfaces

Data Sheet

Data Sheet