Paper

Paper and manufactured board are easy materials to measure with any of our general-purpose infrared temperature sensors. They are generally non-reflective, so excellent results can usually be achieved straight out of the box with default settings.

Choose a sensor with an output type that suits any existing instrumentation, or install a new temperature monitoring system from scratch.

Detailed application notes: textile and paper industry (PDF)

High Ambient Temperatures

For areas where the air temperature is hot, such as the dryers in paper manufacturing, or the single facers in corrugated board manufacturing, our high-ambient sensors such as the PyroMini and PyroMiniBus can be used to good effect. There is no need to supply cooling fluid to the sensors, leading to savings in energy and cost.

Corrugated Board Manufacturing

Existing sensors often have analogue outputs such as thermocouple or 4-20 mA, and are easily replaced with modern, compact, low-cost Calex sensors, such as the PyroCouple.

New installations often suit a multi-channel system with digital RS485 Modbus communications, such as the PyroMiniBus.

Whatever your requirements, Calex has a range of infrared temperature sensors that will be suitable.

Infrared temperature measurement in corrugated board manufacturing (PDF)

Printing

Infrared thermometry has also proved beneficial to printing companies. Both the basic products printers use, and the finished material they produce, have been significantly improved where infrared sensors have been applied.

Detailed application notes: printing and graphic arts (PDF)

Suggested products

-

ST633

Low-cost handheld pocket IR thermometerHandheld Low Temperature (-20 to 500°C) Measures Non-Reflective Surfaces Very Low Temperature (< -20°C)Read more -

Excelog 6

6 Channel Handheld Temperature Data Logger with Touch ScreenContact Probes Data Logging Handheld Multi-Channel PRT Input Pt100 Input RTD Input Temperature Display Thermocouple Input Touch Screen Interface USBRead more -

PyroSigma

Miniature pyrometer with built-in displayAlarm Output High Temperature (500 to 1000°C) Low Temperature (-20 to 500°C) Measures Non-Reflective Surfaces Miniature Temperature Display Very Low Cost Voltage OutputRead more -

PyroMini OEM

Low-cost pyrometer for machine manufacturers4-20 mA Output High Ambient Temperature 120C Low Temperature (-20 to 500°C) Measures Non-Reflective Surfaces Miniature Thermocouple Output Very Low Cost Voltage OutputRead more -

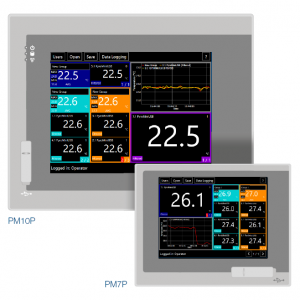

Industrial Panel PCs (Discontinued – contact Calex for alternatives)

PM7P and PM10PData Logging Multi-Channel Networkable RS485 Modbus Touch Screen Interface USBRead more -

PyroMiniUSB

For PC-based data acquisitionData Logging High Temperature (500 to 1000°C) Low Temperature (-20 to 500°C) Measures Non-Reflective Surfaces Miniature Temperature Display USBRead more -

PyroNFC

Smartphone-configurable pyrometer with voltage or thermocouple output - now with iOS app!Alarm Output High Temperature (500 to 1000°C) Low Temperature (-20 to 500°C) Measures Non-Reflective Surfaces Miniature NFC Thermocouple Output Very Low Cost Voltage OutputRead more -

PyroMiniBus

Miniature pyrometer with RS-485 Modbus for multi-channel systemsData Logging High Ambient Temperature 120C Low Temperature (-20 to 500°C) Measures Non-Reflective Surfaces Networkable Relay Output RS485 Modbus Temperature Display Touch Screen Interface Very Low CostRead more -

ST642 (Discontinued – see ST633)

Low-cost handheld IR thermometer with adjustable emissivity and Type K Thermocouple inputHandheld Low Temperature (-20 to 500°C) Measures Non-Reflective Surfaces Thermocouple Input Very Low Temperature (< -20°C)Read more -

PM180

6-channel hub with data logging & alarms0-20 mA Output 4-20 mA Output Data Logging Networkable Relay Output RS485 Modbus Temperature Display Touch Screen Interface Voltage OutputRead more -

PyroCouple

Simple, robust pyrometer with analogue output4-20 mA Output Air or Water Cooling Available Low Temperature (-20 to 500°C) Measures Non-Reflective Surfaces mV Output Thermocouple Output Very Low CostRead more