Tag Archives: Technical Advice

How do you know if your infrared temperature sensor is aimed correctly? Here are some easy ways to improve the alignment of your pyrometer.

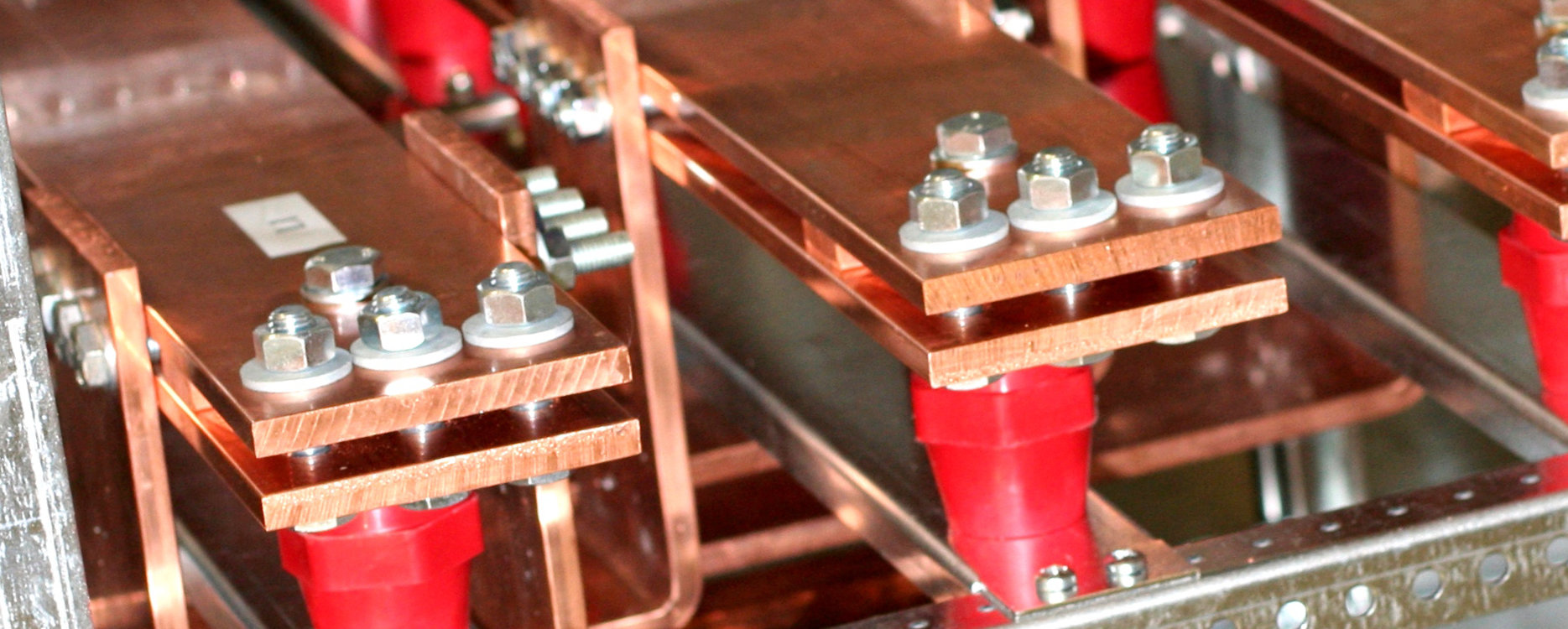

Advancements in the Calex product range make it easier than ever to measure the temperature of busbar joints in switchgear cabinets.

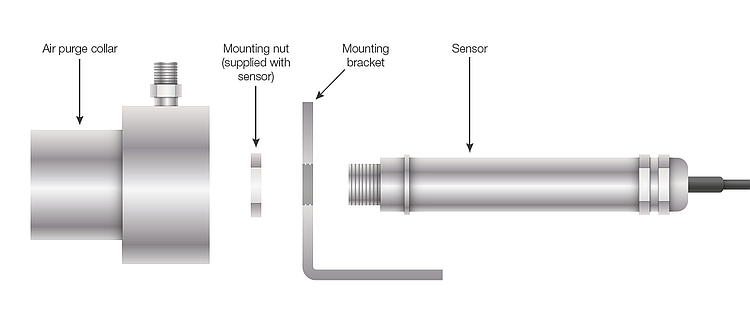

The lens of every infrared temperature sensor must be kept clean and dry to ensure the pyrometer has a clear view of the target. The simplest way to do this is to purge the lens continuously with clean air, preventing dust and moisture from reaching it. Here is how to use the air purge collar.

Measuring the temperature of plastic preforms in blow moulding applications is easy with Calex infrared temperature sensors. An accurate measurement can be obtained as fast as 1 millisecond, even from the smallest preform, without touching the preform.

Calex has achieved success in measuring the surface temperature of extruded aluminium profiles using low-cost non-contact pyrometers. Measurements were taken by a leading manufacturer of extruded profiles at the press exit and after the quench, and good results were obtained with short-wavelength single-wavelength pyrometers, even with significant steam near the quench box.

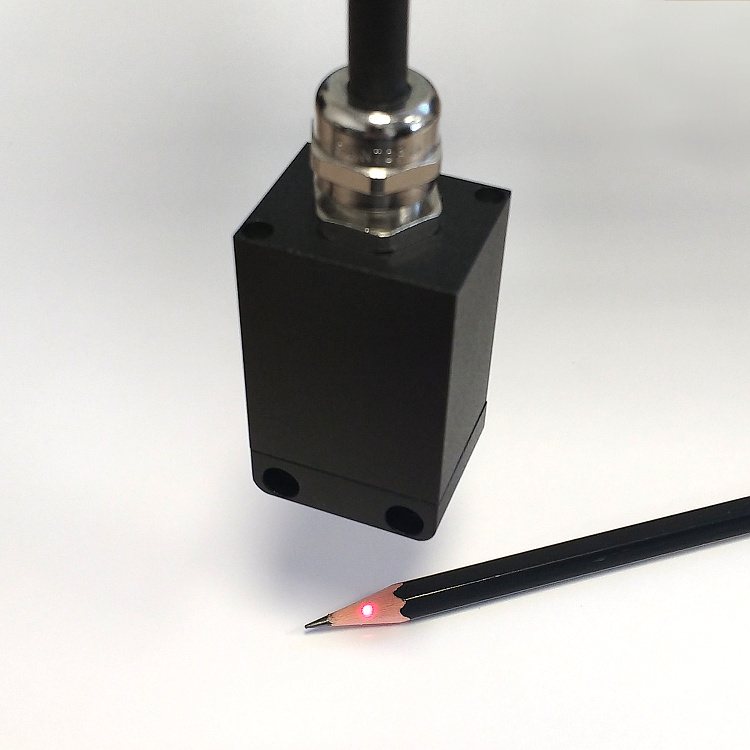

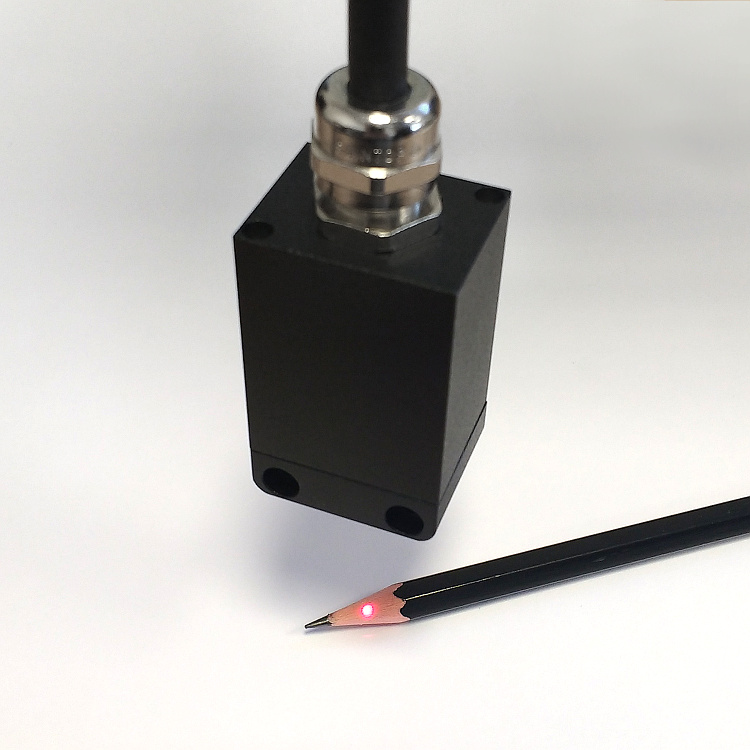

The new PyroUSB series of configurable infrared temperature sensors is now available! All models have a 2-wire, loop-powered 4-20 mA output for industrial process temperature monitoring, and a removable USB cable for configuration and benchtop temperature measurement.

Most infrared temperature sensors have an adjustable emissivity setting. Here’s how to use this powerful feature to achieve accurate measurements from a variety of surfaces.

Non-contact temperature measurement is now possible in areas of high ambient temperature with no need for sensor cooling using air or water. This brings several benefits, including cost reduction, better safety, and improved product quality in manufacturing processes.

Technical advice from Calex Electronics on choosing a suitable infrared temperature sensor to measure small targets.

The PM180 allows a group of infrared temperature sensors to be connected to a Modbus Master as a single device. Here’s how to configure the Modbus Master to communicate with each of the sensors.