Sensor Features

- Temperature range: -20°C to 500°C

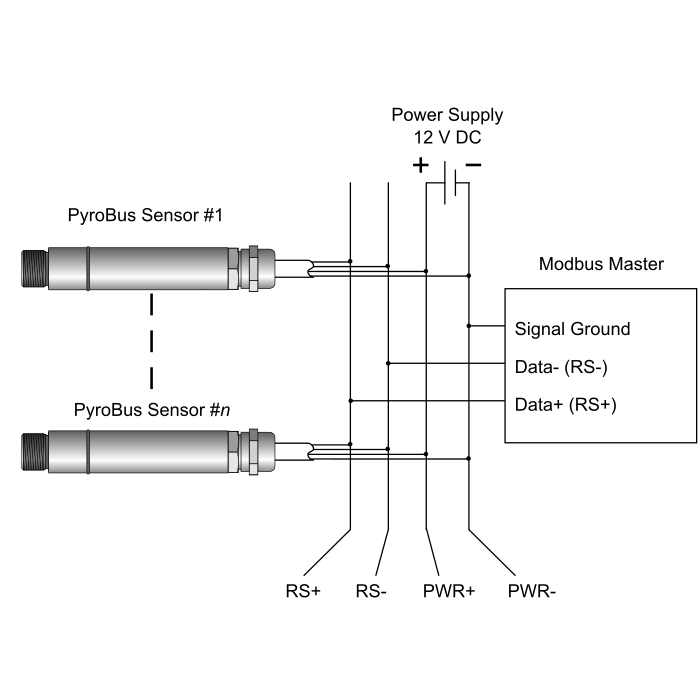

- RS485 Modbus interface

- Up to 247 sensors per network

- Connect to an existing Modbus PLC or a Calex touch screen terminal

- Fully configurable for emissivity, averaging and signal processing

The PyroBus may be installed as a standalone network of sensors, or integrated into an existing Modbus network. Sensors may be connected in a daisy-chain via junction boxes to a single network bus cable, which can significantly simplify cable runs and reduce the cost of cabling compared to using analogue sensors.

For continuous monitoring, PyroBus sensors are significantly lower in cost than thermal imagers, and provide instant, real time temperature data.

There are applications for the PyroBus in a wide range of industries. It is ideal anywhere RS485 Modbus instrumentation exists, or anywhere a large network of sensors is required. For example, some typical uses include:

Typical Applications

For larger requirements, up to 247 sensors can be connected on a single RS485 Modbus network, so whole power distribution rooms can be monitored using networks of these digital pyrometers.

PM180 6-Channel Hub

6-channel touch screen hub for temperature display, alarms, configuration and data logging. Isolated RS485 Modbus master and slave interfaces allow multiple hubs to be connected to a larger network. Optional modules provide analogue and relay outputs.

Air Purge Collar

The air purge collar is used to keep dust, fumes, moisture and other contaminants away from the lens. Air flows into the fitting on the side and out of the aperture at the front.

Fixed Mounting Bracket

The L-shaped fixed mounting bracket offers a rigid support for the sensor and allows fine rotational adjustment about one axis.

Adjustable Mounting Bracket

The adjustable mounting bracket consists of a fixed mounting bracket plus another L-shaped bracket. When assembled as shown, the adjustable mounting bracket offers a rigid support for the sensor and allows fine two-axis adjustment.

Air/Water Cooled Housing

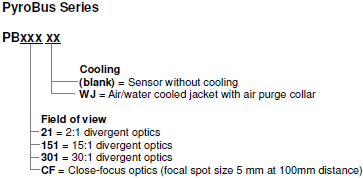

The air/water cooled housing allows the sensor to withstand ambient temperatures above the normal 70°C limit. Depending on the degree of cooling required, air or water may be used as the cooling fluid. To prevent condensation forming on the lens, an air purge collar is included with this item. The air/water cooled housing must be ordered with the sensor and cannot be fitted by the user.

Laser Sighting Tool

The Laser Sighting Tool screws onto the front of the sensor during installation and shows precisely where the sensor is aiming. Once the sensor has been aimed at the centre of the target and locked in position, the Laser Sighting Tool can be removed. The laser is operated via a latching push button on the front of the tool.

Dual Laser Sighting Bracket

The Dual Laser Sighting Bracket is a sturdy mount for the sensor and provides continuous target sighting while measurements are being taken. Two parallel lasers indicate the centre of the measured spot and are controlled by a remote switch on the electronics module.

Protective Plastic Window

When fitted over the lens of the sensor, the protective plastic window in stainless steel holder provides mechanical protection and helps retain fragments of lens in case of damage. Adjust the sensor’s emissivity setting to compensate for the presence of the window for maximum accuracy. This accessory is ideal for the food and pharmaceutical industries.

PyroCouple, PyroEpsilon, PyroCAN data sheet

PyroCouple, PyroEpsilon, PyroCAN data sheet PyroBus Manual

PyroBus Manual